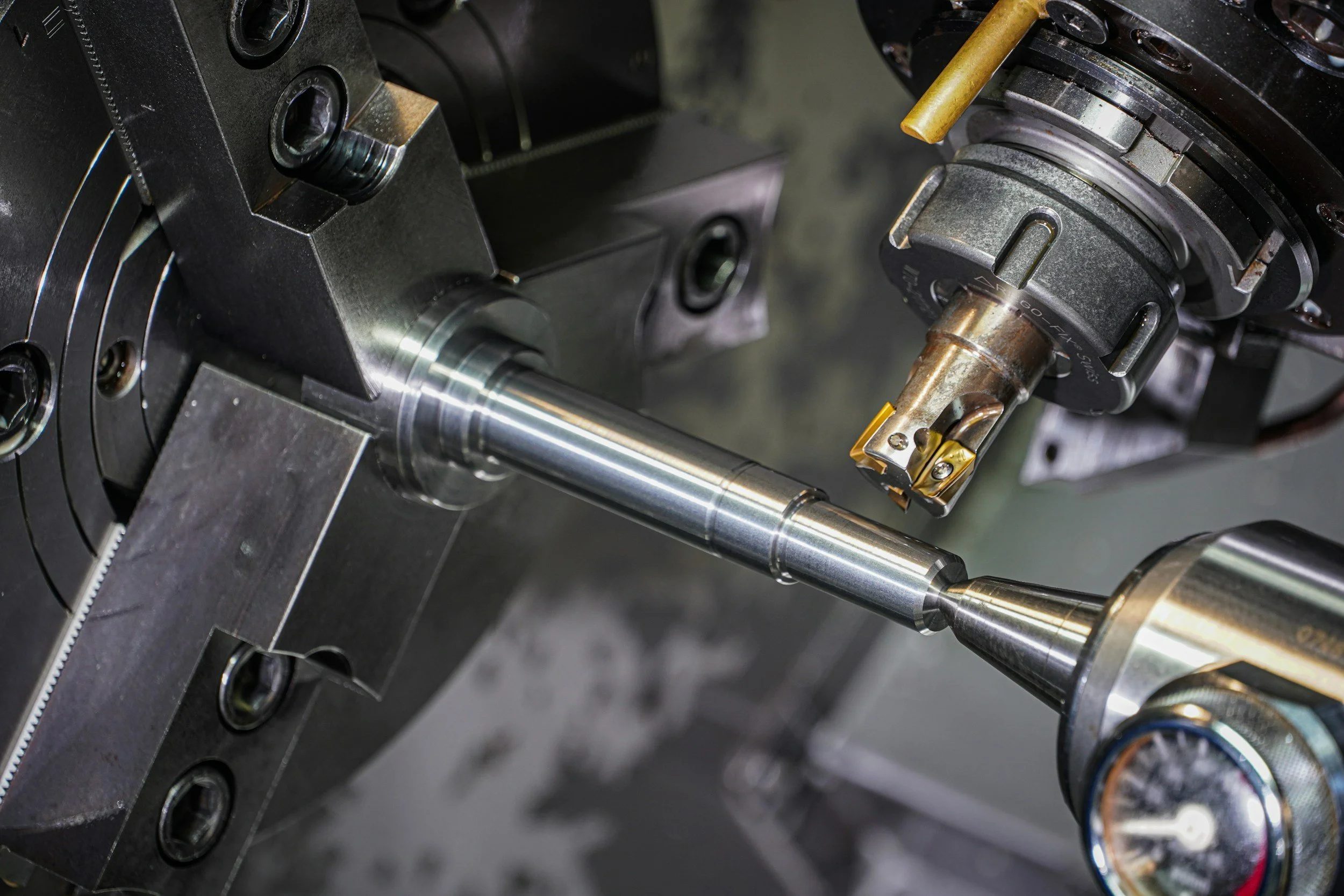

Expert Consulting Solutions for Manufacturing Excellence

Our Services

Interim Operations and Quality Leadership

Delivered a $280M CAPEX project within a percentage point of budget and 3 weeks early.

Integrated cross functional groups into high performance teams. Focused culture on continuous improvement, execution, and accountability.

Eliminate a $800K backorder and removing 400K pieces of inter-company backlog

Increasing First Time Yield from 46% to 78% and reduced customer disruptions by 55% with rigorous Root Cause Corrective Action process.

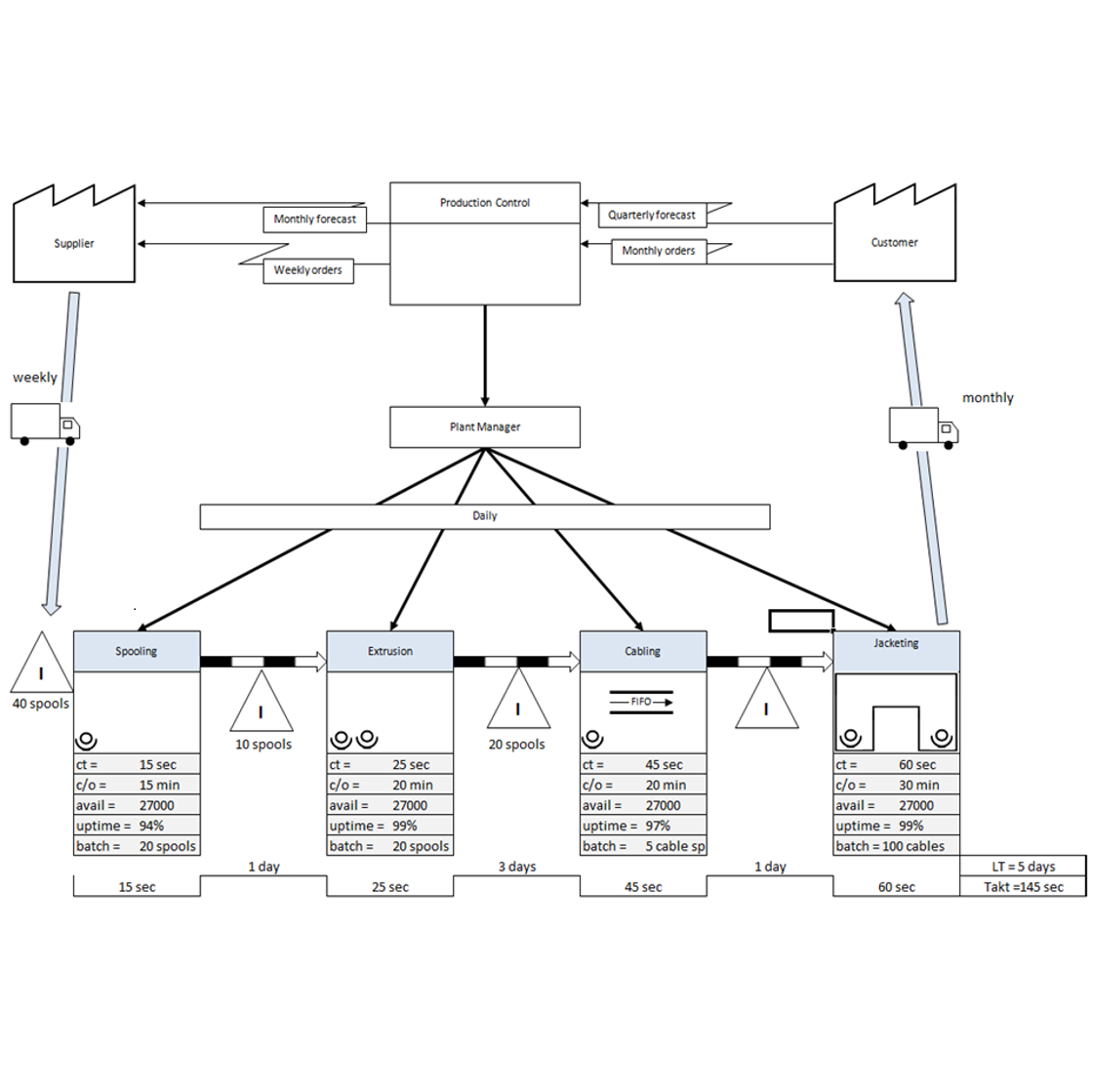

Value Stream Mapping

Reduced lead time by 75% to 5 days. enabling agile response to unforecasted customer demand.

Reduce lead time by 20% and maximize operational efficiency by focusing on quality defects and Work in Progress (WIP) management

Quality Improvement Planning

Identified top drivers for non-conforming parts. Led teams in determining root cause corrective actions; reduced material review board submissions by 22% in 2016.

Developed and managed an aggressive project plan that achieved a 50% reduction in losses.

Reduced customer complaints by 67% with Pareto, Action Plan and Paynter approach.

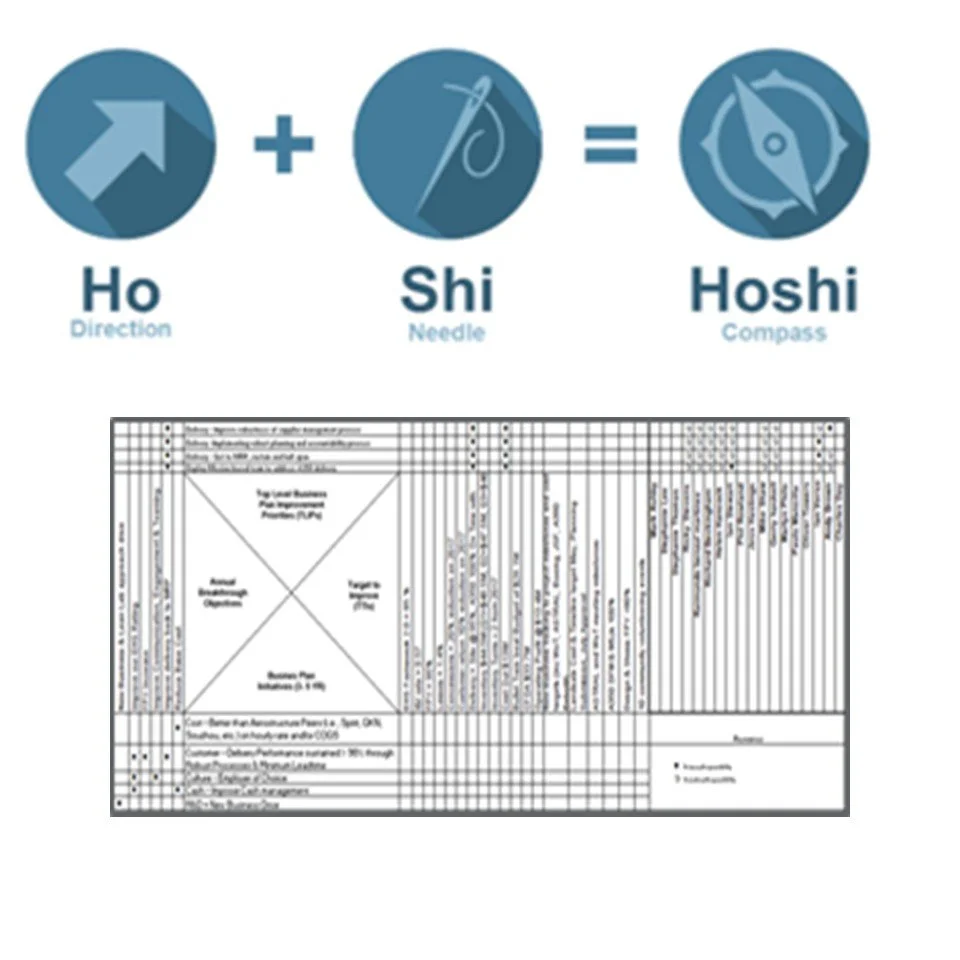

Hoshin Kanri Facilitation

Increased margin by one percentage point without layoffs, by aggressively controlling costs during market downturn,

Reduced recordables by 57% and injuries by 54%, with culture of operational excellence in safety

Cultivated an operational-oriented safety culture through direct engagement, achieving an average 97% participation rate.

About

Highly seasoned operations leader with over 30 years of experience in plant management, strategic planning, and process improvement.

https://www.linkedin.com/in/william-dobbs/

Contact Us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!